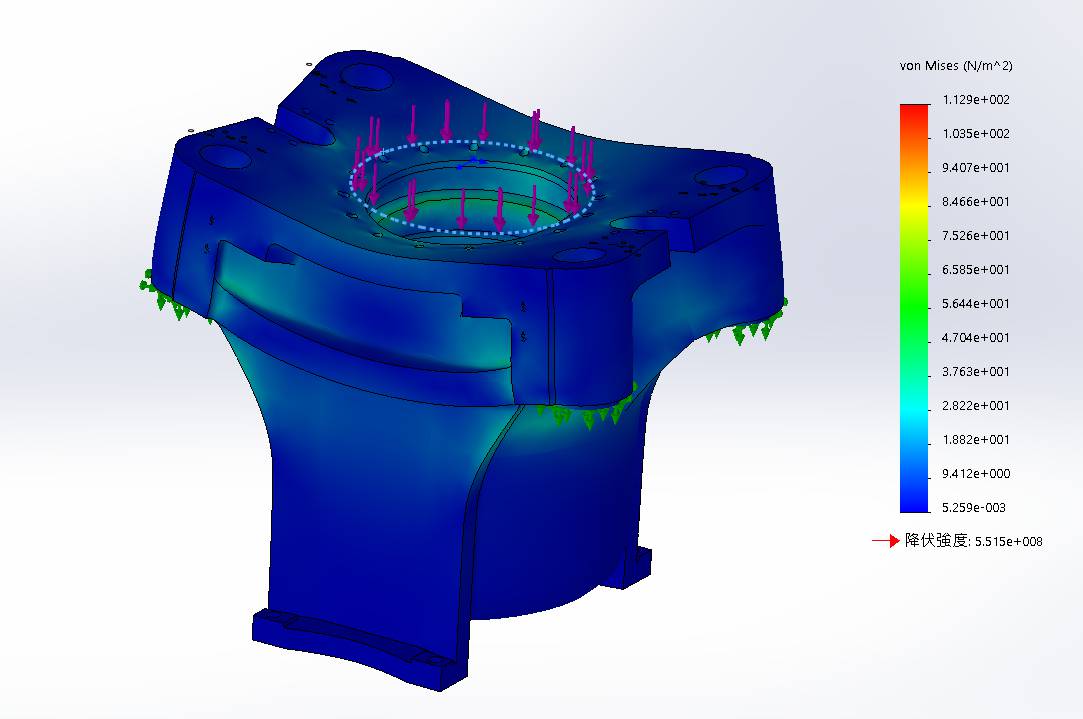

Stronger Structural Design

The pressure-bearing structure undergoes stress analysis to reduce structural deformation during high output pressure situations.

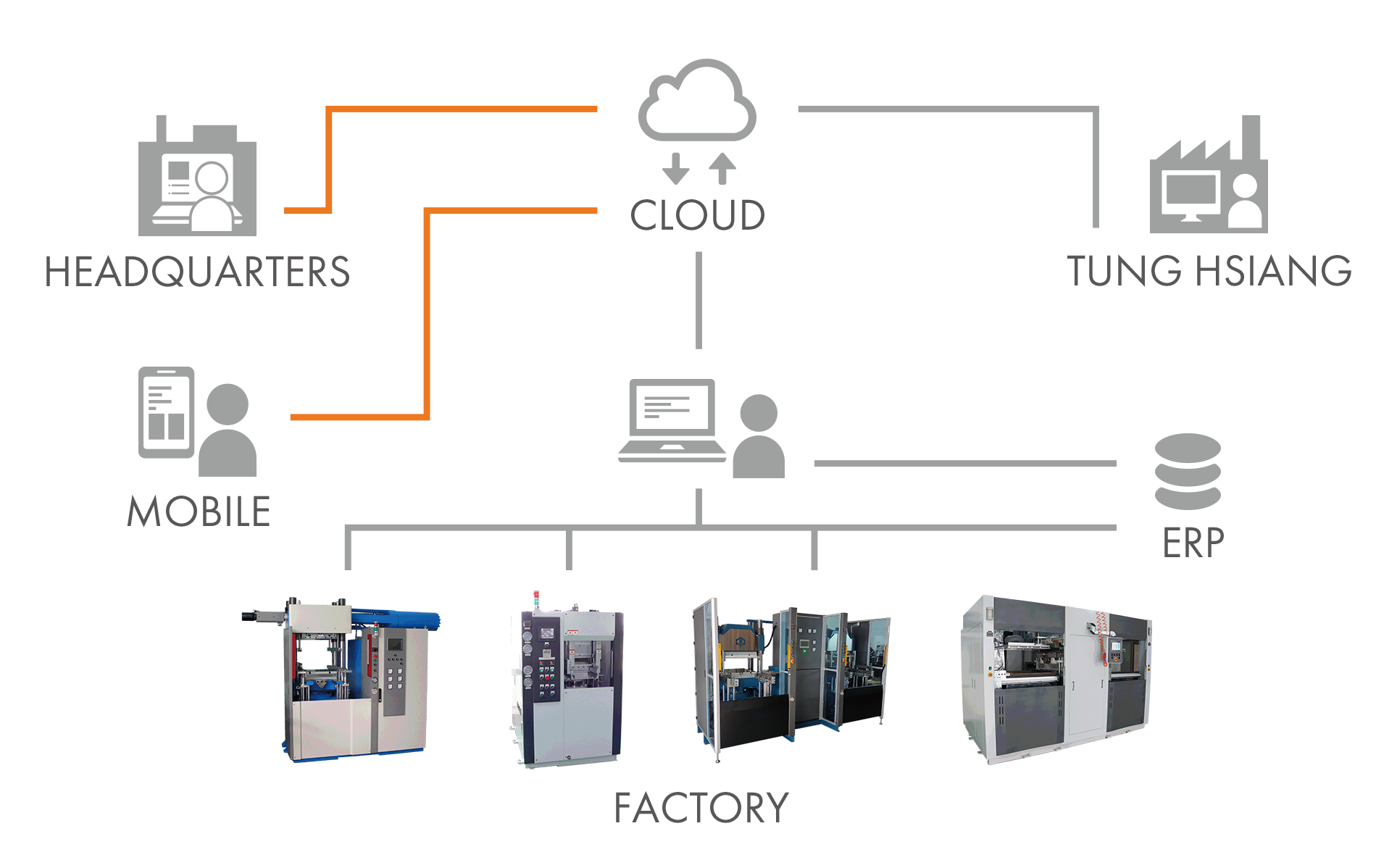

To achieve a smarter intelligent production process

1. Enable real-time monitoring and feedback of equipment status to the production management system.

2. Collect and manage production equipment information, process data, and workflow in a centralized system for efficient production process control.

For more efficient production management

Regardless of their location, managers can remotely access and monitor equipment status through remote connectivity.

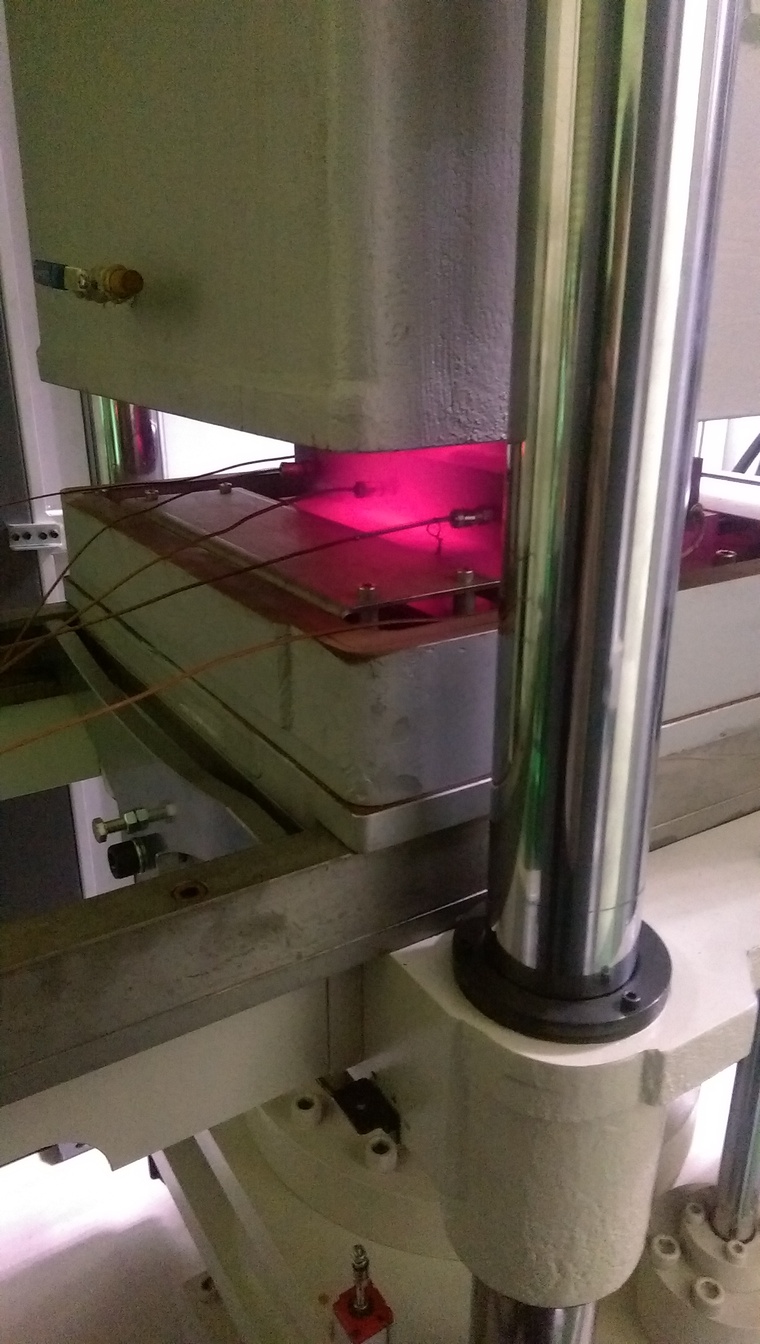

To achieve higher energy-efficient molding processesTo accommodate high-temperature hot press processes exceeding 600 degrees Celsius and specialized metal forming and powder sintering processes, consider the following.

For precise molding positioning

To enhance molding processes with CCD visual alignment and inspection assistance.

To create a cleaner production environment

To implement full electric or hybrid electric-hydraulic hot press molding technology in a dust-free environment.

For more precise molding control

Utilize closed-loop servo valves for accurate pressure control at a precision of 0.1 kg/cm², ensuring consistent and controlled molding pressure.

To enhance production efficiency

Tailor a hot-press molding automation system according to your requirements to make the production process faster and more efficient.

Higher energy utilization efficiency

Oil-electric servo precise control of pressure and flow for each action, eliminating energy waste during inactive periods.