All Products

-

Read More

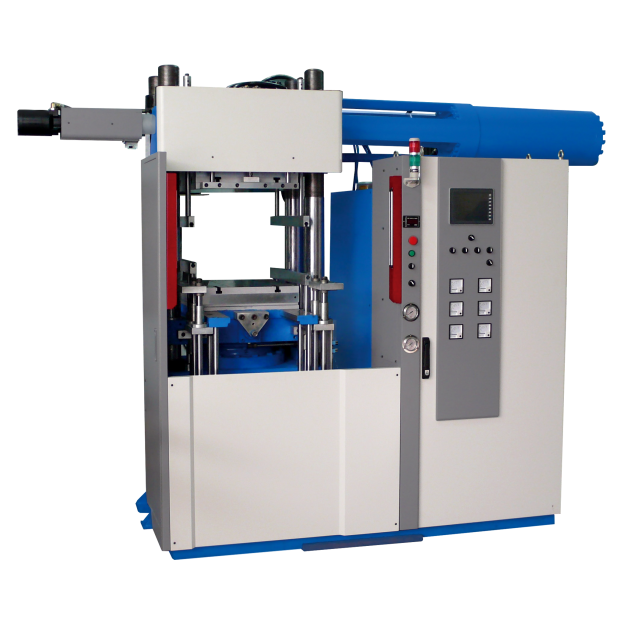

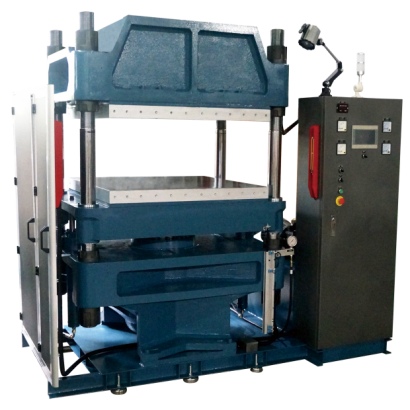

HT Series

HT SeriesHT Series

Hot press, molding, and high-pressure gas-assisted forming for high-temperature materials, target materials, powders, and aluminum-magnesium alloy plate. -

Read More

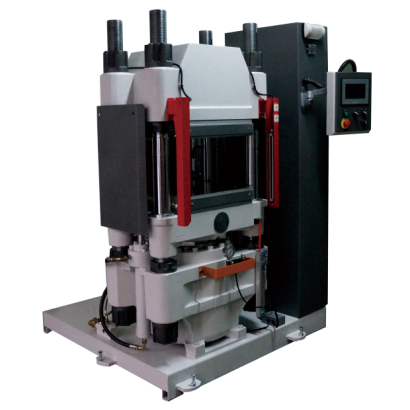

Manual hot press machine

Manual hot press machineManual hot press machine

1. In the era of automated manufacturing processes, certain industries still rely on irreplaceable manual hot forming techniques, where the artisan's touch embodies a level of warmth that machines cannot achieve.

2. Simple and straightforward sample hot press tests do not require overly complex operat. -

Read More

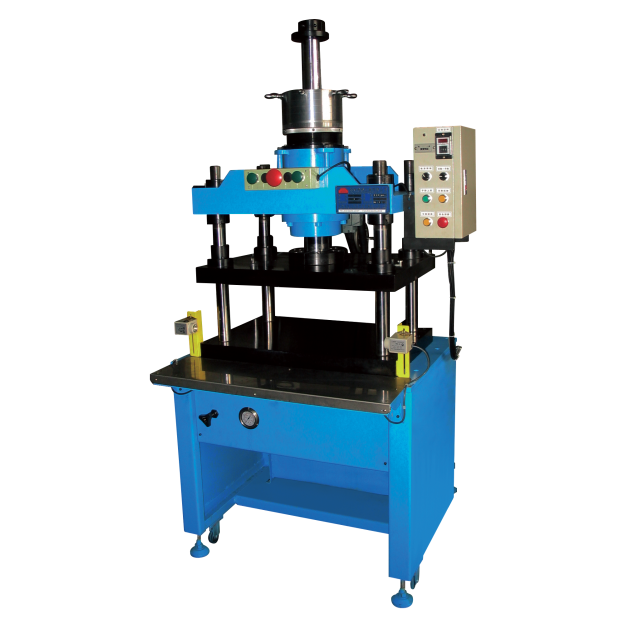

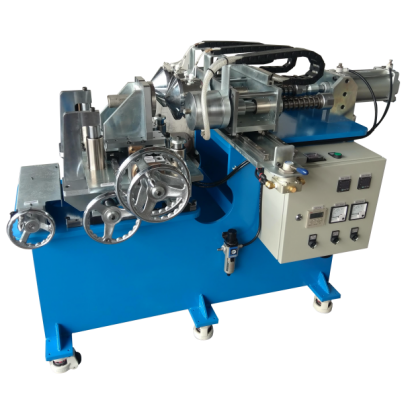

Metal and composite material molding machine, punch machine, leveling machine.

Metal and composite material molding machine, punch machine, leveling machine.Metal and composite material molding machine, punch machine, leveling machine.

It can punch, cut, and level metal sheets and composite materials. -

Read More

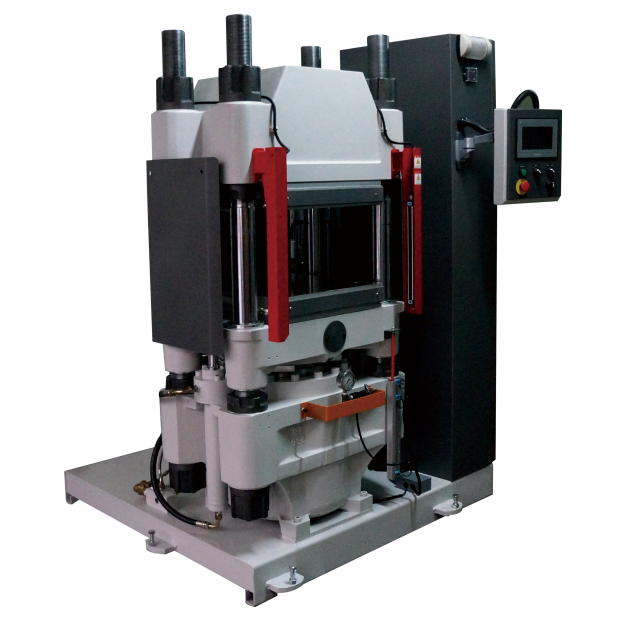

Carbon fiber hot pressing molding equipment

Carbon fiber hot pressing molding equipmentCarbon fiber hot pressing molding equipment

Carbon fiber and sheet hot pressing molding, including rapid cooling and heating equipment for molding. -

Read More

Small vacuum hot press testing machine

Small vacuum hot press testing machineSmall vacuum hot press testing machine

Specializing in small vacuum hot press testing machines for testing purposes. -

Read More

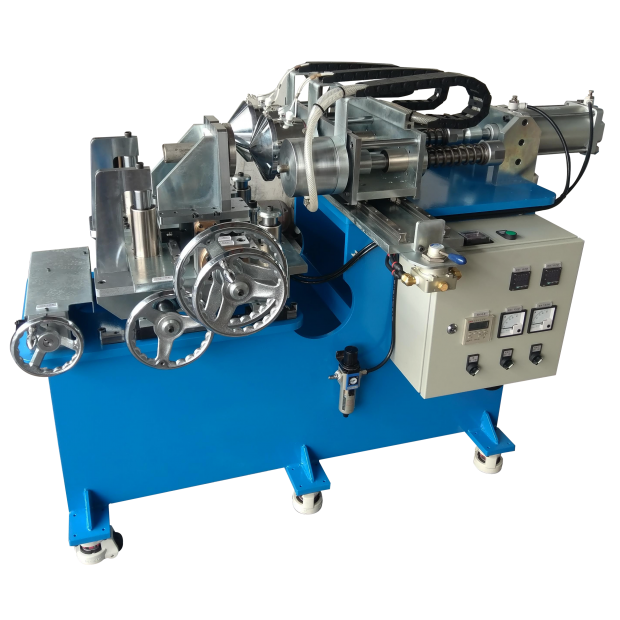

Resin bond diamond (CBN) grinding wheel molding machine.

Resin bond diamond (CBN) grinding wheel molding machine.Resin bond diamond (CBN) grinding wheel molding machine.

Specifically designed for resin bond diamond (CBN) grinding wheel molding, can be equipped with mold cooling mechanism. -

Read More

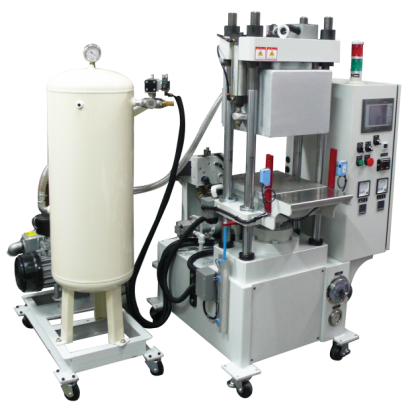

Small hydraulic press, film forming machine, hydraulic press

Small hydraulic press, film forming machine, hydraulic pressSmall hydraulic press, film forming machine, hydraulic press

Specifications are customized according to customer requirements. -

Read More

Valve pressure testing machine, pressing machine.

Valve pressure testing machine, pressing machine.Valve pressure testing machine, pressing machine.

The pressure testing medium can use hydraulic and pneumatic pressure to test the valve leakage rate and pressure resistance. We design and manufacture complete plant valve testing equipment for pressure testing, leak testing, and lifespan testing. -

Read More

Butterfly valve assembly equipment

Butterfly valve assembly equipmentButterfly valve assembly equipment

Automated assembly of rubber rings into the butterfly valve body, saving labor costs, increasing productivity. Currently capable of assembling 2 to 8-inch butterfly valves, used by several butterfly valve manufacturers.